Effluent Treatment Plant. It is a stirred tank.

Bubbling Fluidized Bed Reactor Chemical Engineering World

Enter the email address you signed up with and well email you a reset link.

. Catalyst can be continuously regenerated with the use of an auxiliary loop. Kinds of Phases Present. Design Operation And Analysis Of Waste Water 25 Integrated Fixed Film Activated System IFAS addition of fluidized bio-media has been implemented to meet these requirementsThis hybrid process of fluidized media and activated sludge process taking place in a single aeration tank is known as Integrated Fixed Film.

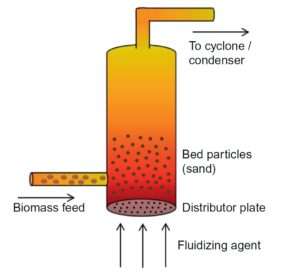

The flue gas produced by the boiler enters from the bottom of the desulfurization tower after. Consequently more advanced designs have evolved that use a hot gas stream such as in a fluidized bed of sand to heat the feedstock quickly and evenly 36. 1 shows the circulating fluidized bed flue gas desulfurization technology.

Alternatively dynamic heating protocols have been utilized in which the feedstock co-fed with sand to improve the efficiency of the transfer of heat is moved through the reactor along a hot auger screw 37 or rotating cone. As shown in Figure II4 in the United States the ethanol industry is dominated by corn with 915 percent of production capacity from facilities using corn alone and another 79 percent of capacity from facilities using a blend of corn and other grain eg corn and milo. The semi-dry desulfurization technology can be applied to the fluidized bed and the typical equipment is the circulating fluidized bed flue gas desulfurization tower.

Expatica is the international communitys online home away from home. With in-depth features Expatica brings the international community closer together. To retrieve emissions factors select one or more search terms from the dropdown menus below then click on the Submit Search button at.

An HRSG is a kind of heat exchanger that recovers heat from the exhaust gases of a gas turbine to an extreme degree. Good uniformity of temperature. WebFIRE contains the EPAs emissions factors for criteria and hazardous air pollutants HAP for industrial and non-industrial processes.

A must-read for English-speaking expatriates and internationals across Europe Expatica provides a tailored local news service and essential information on living working and moving to your country of choice. Heterogeneous has phase reactions with a catalyst. It is not a column reactor like a circulating fluidized bed or a column reactor in which the particles and the fluid move counter-currently and it does not contain a particle bed.

The terminology moving bed biofilm reactors commonly employed in association with wastewater treatment is in fact a misnomer. A heat recovery steam generator HRSG is one of the major pieces of equipment in a gas turbine combined cycle power plant that boasts a high thermal efficiency and produces minimal CO 2 emissions. Like a CSTR in that the reactants are well mixed.

Current commercial production of ethanol is based almost exclusively on starch- and sugar-based feedstocks.

Bubbling Fluidized Bed Reactor 76 Download Scientific Diagram

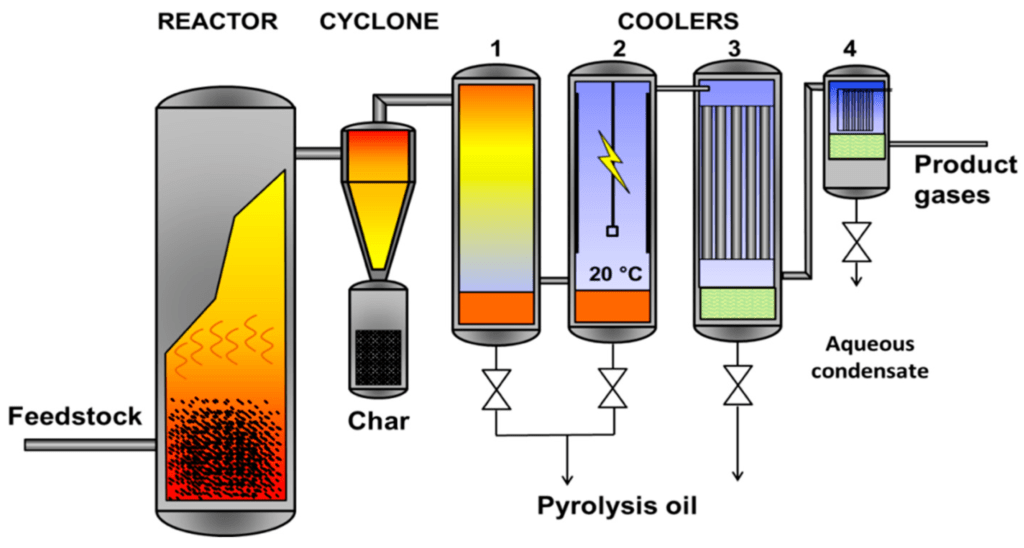

Process Schematic For Bubbling Fluidized Bed Download Scientific Diagram

Bubbling Fluidized Bed Reactor Chemical Engineering World

A Schematic Representation Of The Bubbling Fluidized Bed Reactor Esp Download Scientific Diagram

Bubbling Fluidized Bed Reactor With An Electrostatic Precipitator Download Scientific Diagram

Schematic Diagram Of A Bubbling Fluidized Bed Reactor Download Scientific Diagram

Two Phase Model To Present The Bubbling In Fluidized Bed Reactor Download Scientific Diagram

0 comments

Post a Comment